1. CNC milling technology

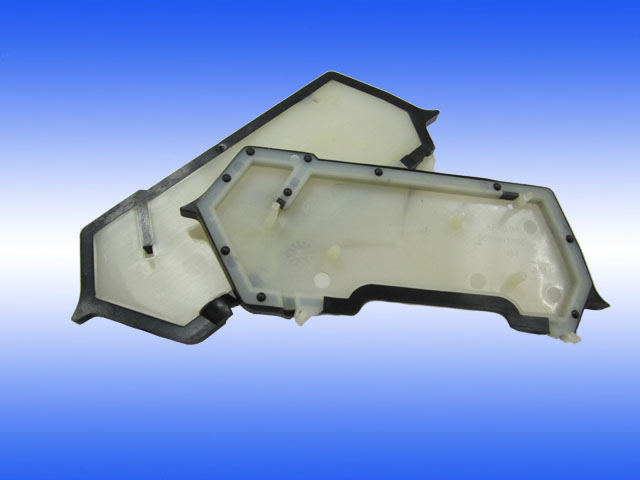

The processing technology of the parts is based on CNC milling; previously, it is evolved from ordinary milling machine; so far, it has been developed from three-axis to five-axis processing, so that it can process complex mold parts with CNC milling, even 3D parts;

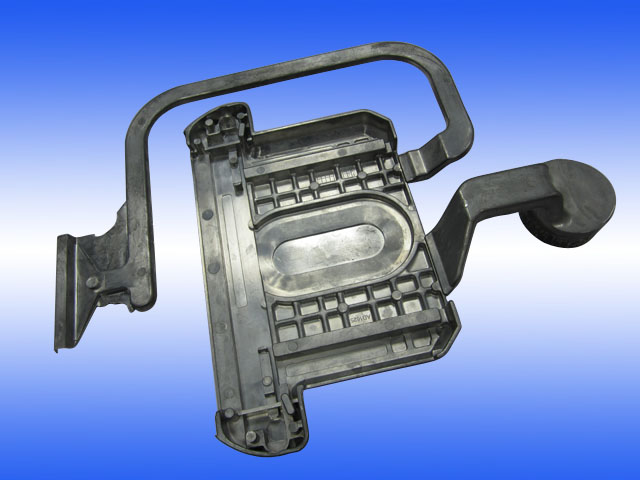

2. Wire-cutting technology

Another technology for processing of mold parts is low-speed wire-cutting electrical discharge machining (LSWEDM); at present, many plastic mold parts are produced with LSWEDM, such as the common slider in injection mold; however, such method can only be used for molds with lower accuracy;

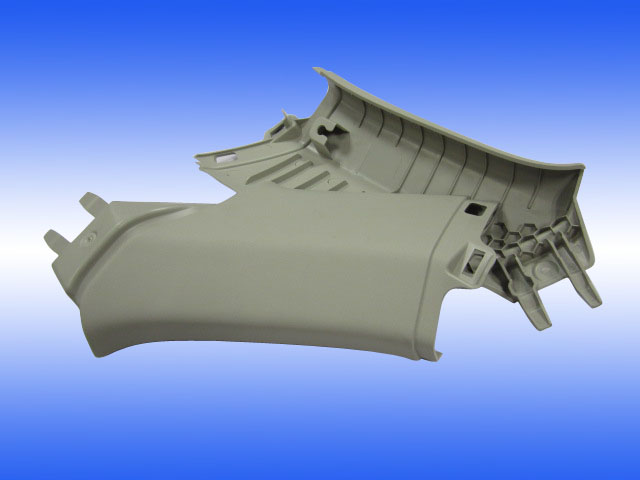

3. Grinding technology

High-quality mold parts also use grinding technology, because it is the main method for processing of precision parts, in particular the parts in precision instruments and equipment; the small flat grinding machine is used for the mold parts in small size, and the large hydraulic grinding machine is used for components in large size; when processing the mold parts, the grinding machines shall be selected depending on the types;

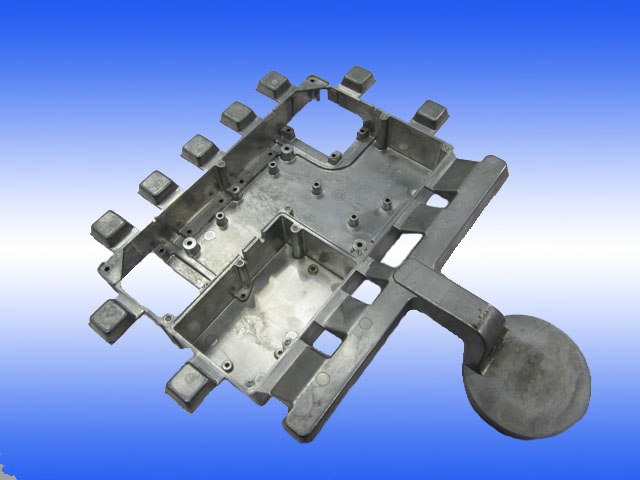

In addition to the above three technologies, another well-known one is the electric discharge technology mainly used for complex mold parts, especially parts with deep groove, because the electric discharge can implement deep cutting and achieve higher success rate for cutting, which is impossible for other existing technologies. In addition, the cost of electric discharge processing is lower than that of cutting tool-based processing.