Abstract: metal stamping is a kind of forming processing method that uses punch and stamping die to exert external force on sheet, strip, pipe and profile, so as to produce plastic deformation or separation, so as to obtain the required shape and size of workpiece (metal stamping parts). Metal stamping and forging belong to plastic processing (or pressure processing), collectively known as forging. There are many kinds of blank for metal stamping: ordinary hot-rolled and cold-rolled steel plate and strip; various types of stainless steel, such as sus201202, sus3034316, sus430439, etc.; copper alloy such as brass, phosphor copper, red copper, pure aluminum and aluminum alloy, etc.; with the trend of lightweight automobile body, more and more high-strength alloy steel is used for automobile stamping parts.

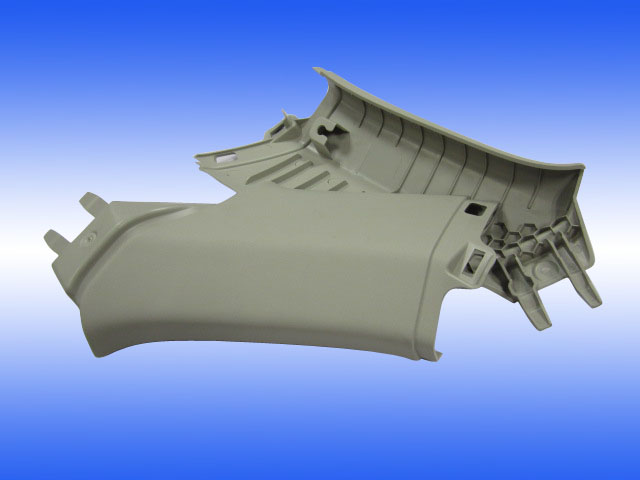

After hot rolling and cold rolling, the thickness of steel plate gradually becomes thinner. Automobile body, chassis, oil tank, radiator plate, boiler drum, container shell, motor, electrical core silicon steel plate are all processed by automobile stamping die. In instruments, household appliances, bicycles, office machinery, household utensils and other products, metal stamping dies are also used for processing.

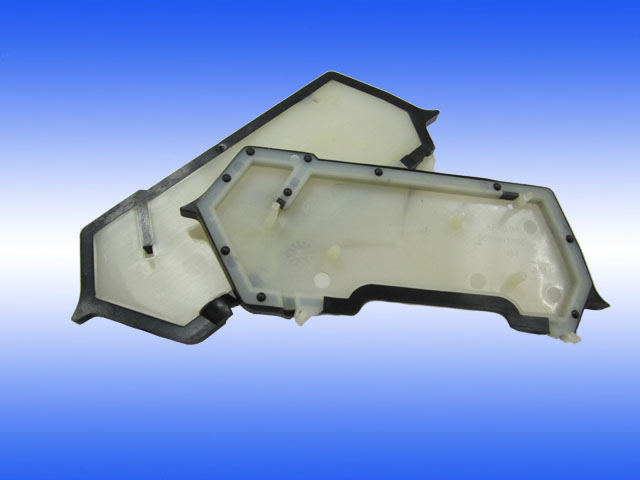

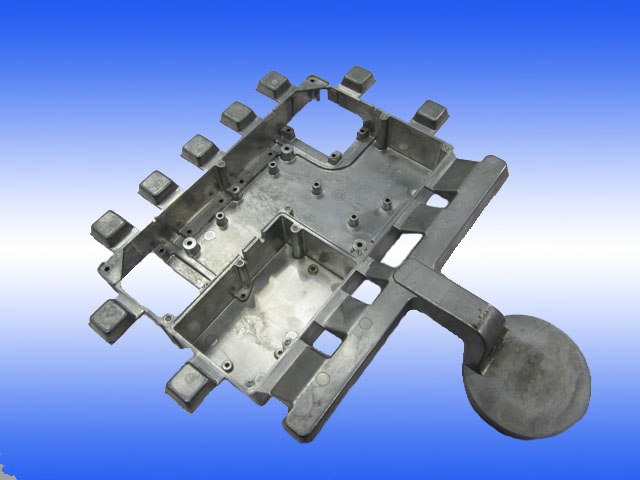

Compared with castings and forgings, metal stamping parts are thin, uniform, light and strong. Metal stamping can produce workpieces with stiffeners, ribs, undulations or flanging that are difficult to manufacture by other methods, so as to improve their rigidity. Due to the use of precision stamping die, the precision of the workpiece can reach micron level, and the repetition precision is high, the specification is consistent, and the hole socket and boss can be punched out by hardware.

Cold stamping hardware stamping parts generally no longer need cutting processing, or only a small amount of cutting processing. The accuracy and surface state of hot stamping parts are lower than that of cold stamping parts, but still better than that of castings and forgings, with less machining.

Metal stamping is an efficient production method. By using compound die, especially multi position progressive die, multiple metal stamping processes can be completed on one punch, realizing the automatic production from uncoiling, leveling, punching to forming and finishing. It has high production efficiency, good working conditions and low production cost. Generally, it can produce hundreds of pieces per minute.

Types of metal stamping process:

Metal stamping is mainly classified by process, which can be divided into two categories: separation process and forming process. The purpose of the separation process, also known as blanking, is to separate the metal stamping parts from the sheet along a certain contour line and ensure the quality requirements of the separation section. The purpose of forming process is to make the sheet metal plastic deformation without breaking the blank, and to make the required shape and size of the workpiece. In actual production, it is often a variety of processes applied to a workpiece. Punching, bending, shearing, drawing, bulging, spinning and straightening are the main metal stamping processes.

The surface and internal properties of metal stamping materials have a great influence on the quality of metal stamping products, which requires that the thickness of metal stamping materials is accurate and uniform; the surface is bright and clean, without spots, scars, scratches, surface cracks, etc.; the yield strength is uniform, without obvious directionality; the uniform elongation rate is high; the yield strength ratio is low; the processing hardenability is low.

In the actual production, it is often used to test the stamping performance of materials, such as drawing performance test, bulging performance test and so on, in order to ensure the quality of finished products and high qualified rate.

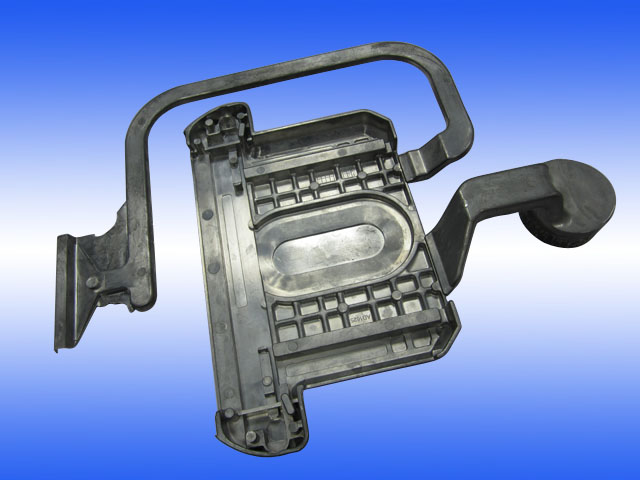

The precision and structure of stamping die directly affect the forming and precision of metal stamping parts. The manufacturing cost and service life of stamping die are the important factors that affect the cost and quality of metal stamping parts. The design and manufacture of stamping die need more time, which prolongs the production preparation time of new hardware stamping parts.

Standardization of die base, die base and guide parts, development of simple stamping die (for small-scale production), compound die, multi position progressive die (for large-scale production), and development of rapid die change device can reduce preparation workload and time of metal stamping production, reduce preparation workload and time of metal stamping production, and make it suitable for large-scale production Advanced metal stamping technology is reasonably applied to small batch and multi variety production.

Metal stamping equipment in addition to the thick plate forming by water press, generally use mechanical punch. With modern high-speed multi station mechanical punch as the center, equipped with uncoiler, leveling, finished product collection, conveying and other machinery, as well as stamping die library and rapid die change device, and controlled by computer program, a high productivity automatic metal stamping production line can be formed.

When tens or hundreds of metal stamping parts are produced per minute, the processes of material feeding, metal stamping, parts discharging and waste discharging are completed in a short period of time, which often lead to personal, equipment and quality accidents. Therefore, the safety production of metal stamping is a very important problem.

Develop the metal stamping industry in case of resistance to seek breakthrough:

According to statistics, in 2003, China produced about 2.4 million tons / 800 million stamping parts for automobiles, 280000 tons / 1.9 billion stamping parts for motorcycles, 960000 tons / 710 million stamping parts for tractors and agricultural vehicles, and 1 million tons / 1.28 billion stamping parts for household air conditioners and refrigerators. Industry experts predict that with the rapid development of automobile industry, the largest user market of metal stamping industry in the future, China's metal stamping industry has ushered in a period of rapid development opportunities, but whether to seize the opportunity to obtain new and faster development, experts point out that there are still many obstacles and obstacles to overcome and break through on the way forward.

Resistance I: low mechanization and automation

70% of 680 metal stamping lines in the United States are multi position presses, and 32% of 250 production lines in Japan are multi position presses,