1. To provide more services to form the industry chain

At present, generally Chinese private mold enterprises have advanced equipment resources, and apply the advanced technology for precision mold parts, so that the new technology can be used in the industry widely and quickly, so as to form the industry chains in design and manufacturing, and production and thermal treatment of relevant materials with prominent integration advantages. At present, due to sufficient capital and independent brands, the hardware mold enterprises increase investment in management and technical transformation, increase the proportion of high-end products, and set up the domestic sales department to actively expand their Chinese market.

2. To reduce resource consumption and waste discharge

Promote industrial circular economy pilot for domestic precision mold parts, reduce resource consumption and waste discharge on the principles of reduction, recycling, and resource transformation, actively implement preferential policies for comprehensive utilization of national resources, and carry out the recycling of waste battery, waste appliances and furniture, and reprocessing of residues of bamboo and wood, mine waste, sludge of sewage treatment plant, and residues of stainless steel.

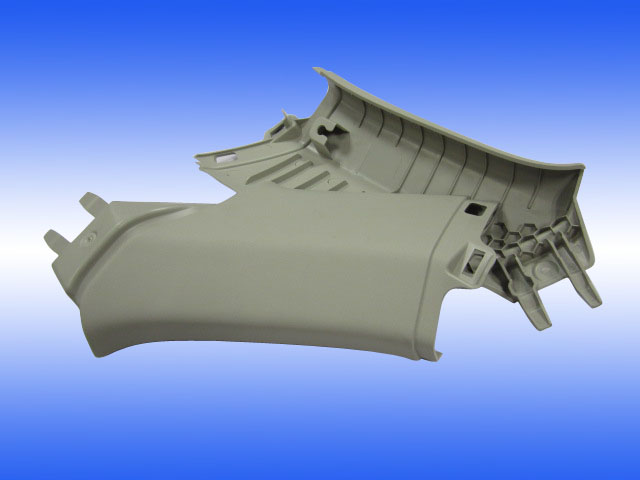

3. To achieve processing of fine areas easily

The precision mold parts processing shall achieve high precision, smooth surface of parts, and processing of fine areas easily. The tolerance of precision mold parts is increased during the semi-finishing process, so as to save the calculation time. The tool selected is smaller than that that for finishing, or the back chipping shall be carried out in advance to prevent bumping at corners during finishing.

In a word, if the fixed axis milling used in precision mold parts processing is found during the actual processing, the capacity of PTP file output will be larger, especially if the finishing is selected. Another arc interpolation method is provided for high-quality precision mold parts. After processing, the size of PTP file is reduced, so as to decrease the pre-reading load of machine tool, and maintain high smoothness and surface quality at a high feeding speed.