In recent years, the number of China's metal stamping manufacturing enterprises is increasing, and the production capacity is also increasing. However, most of them are small and medium-sized enterprises, with limited investment in equipment and R & D, which mainly produce low-end stamping products with low technical requirements, resulting in relatively saturated supply and fierce competition in the low and medium-end market, while the domestic self-sufficiency rate in the high-end market is still low, only about 60%. Some of the leading domestic metal stamping production enterprises, through the introduction of foreign advanced production equipment and technology, strengthen technological research and development and production process innovation, to improve product manufacturing to a new height.

According to the analysis report on market supply and demand situation and development prospect of China's precision metal processing industry in 2017-2022 issued by xinsijie Industrial Research Center, during the 12th Five Year Plan period, China's stamping industry has 25000 manufacturing enterprises, 2 million employees, 28 million tons of stamping parts annually, with a total sales volume of 400 billion yuan. Taking the automobile industry as an example, at present, domestic enterprises have achieved the design and manufacturing of C-class automobile dies, and the large-scale continuous stamping dies have made substantive breakthroughs. They have successfully developed a large-scale continuous stamping die with a length of 6m. They compete with international manufacturers in the high-end automobile die product segment market in all aspects, promoting the rapid development of the import alternative market and the pace of localization of stamping dies Step up. Chery, great wall, brilliance and other independent brand automobile enterprises have successively shifted the whole vehicle mould required for automobile development from import to domestic procurement, while joint ventures such as Volkswagen and general motors have also begun to shift the high-end automobile mould to domestic procurement. The localization of high-end automobile mould has further expanded the market demand of domestic automobile stamping products.

Barriers to entry into the precision metal stamping industry are:

1. Technical barriers

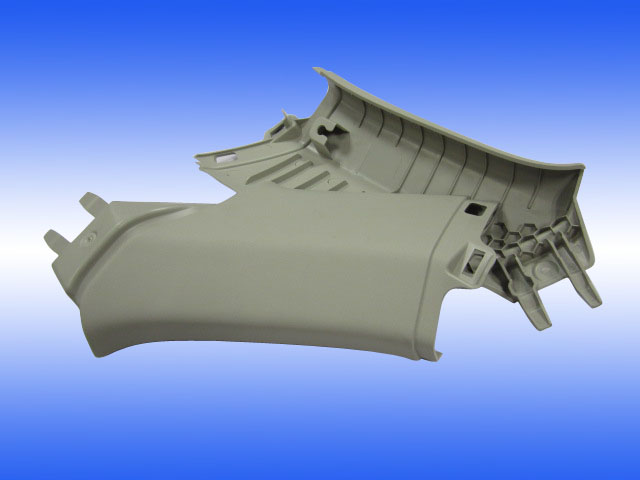

Precision metal stamping industry is a technology complex industry which integrates metal manufacturing, new material application, stamping die design and manufacturing, information technology and other aspects. The downstream industries are mainly automobile, electronic communication and other industries, which have high requirements for the processing accuracy and product quality of metal stamping parts, thus putting forward strict requirements for the technical ability in the process of product development and manufacturing, making the existing enterprises in the industry have strong technical level, forming a technical barrier to the later.

2. Market barriers

Metal stamping parts are a part of a complete commodity, so enterprises in the metal stamping industry need to have certain industry experience in the industry of their customers. In particular, the company's current main service object is manufacturing industry, across electronic, automotive, communications and other industry customers, customers will pay attention to the company's past industry success stories, whether it has the ability to independently develop mold, and the industry experience barrier is high. At the same time, through long-term and good service, advanced entrants can establish a good customer base and accumulate a wealth of successful cases in their competitive field, so as to establish a good market brand image and have a stable and loyal customer group, while new entrants are difficult to cultivate a stable customer group in the short term.

3. Financial barriers

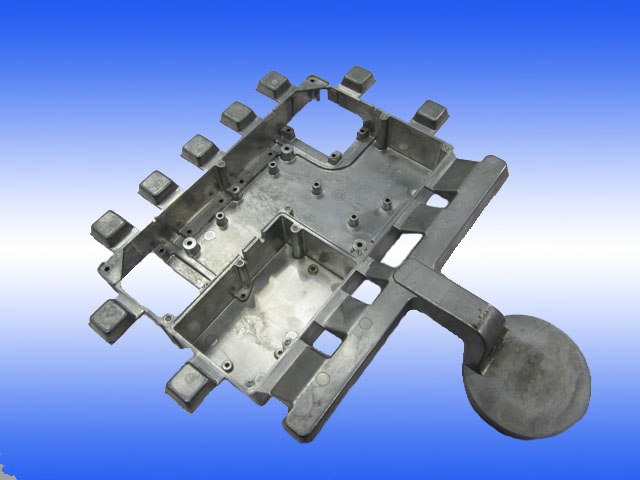

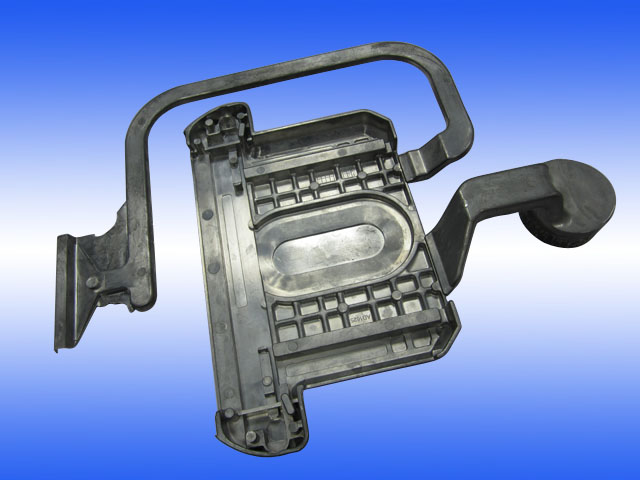

High quality hardware stamping parts need advanced equipment and high-quality stamping die to cooperate with each other, which requires hardware stamping enterprises to introduce expensive hardware die design software, die processing equipment and advanced stamping equipment. And it needs to have the ability of technological innovation and new product R & D to upgrade and update with customers' products simultaneously. Therefore, large-scale specialized metal stamping production enterprises must have enough funds to invest in equipment and R & D, which forms a financial barrier for new entrants. Dongguan Xieyu mould Co., Ltd. specializes in the design and manufacture of metal mould, and independently develops and designs large stamping mould within 4m.

According to analysts of xinsijie industry, during the 12th Five Year Plan period, the stamping industry has made a series of progress in the selection of new materials, the renewal of stamping equipment and stamping dies, the improvement of stamping technology, and the development and application of software. Although the information and digital construction of stamping industry has not started for a long time, it has significantly improved production efficiency and product quality, and achieved considerable economic and social benefits. It is predicted that during the 13th Five Year Plan period, with the steady improvement of China's GDP and industrial added value, the market capacity of precision metal stamping industry will further expand.