1. Stamping material performance

There are different strength automobile stamping parts on the automobile body, from ordinary plate to high-strength plate, different plates have different yield strength, the higher the yield strength of the plate, the more prone to springback phenomenon. For example, s500mc and DP780 are high-strength steel plates with good cold forming performance.

2. Thickness of stamping material

In the process of metal stamping, the thickness of sheet metal has a great influence on the bending performance. As the thickness of sheet metal increases, the springback phenomenon will gradually decrease. This is because as the thickness of sheet metal increases, the materials involved in plastic deformation will increase, and then the elastic recovery deformation will also increase. Therefore, the springback will decrease.

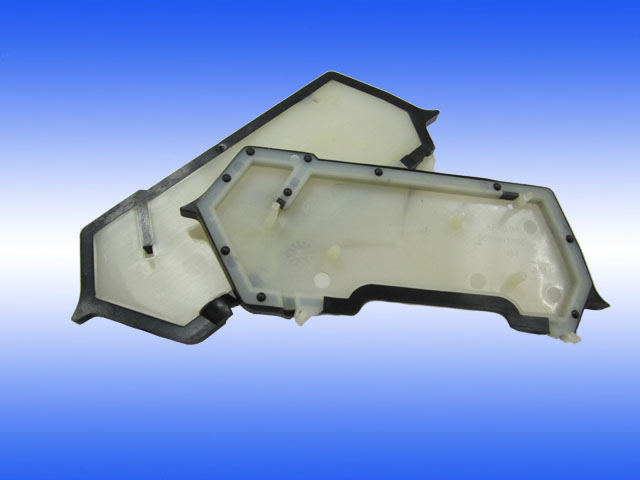

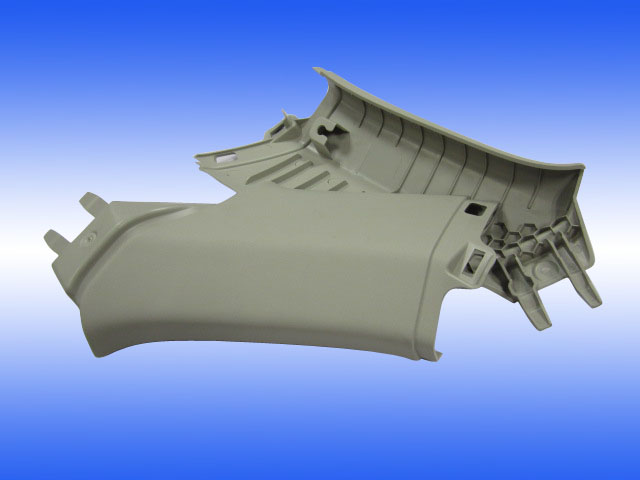

3. Shape of stamping parts

There are great differences in springback of parts with different shapes. For parts with complex shapes, a sequence of shaping is generally added to prevent springback phenomenon due to improper forming. For some parts with special shapes, springback phenomenon is more likely to occur, such as U-shaped parts. In the analysis of forming process, springback compensation of stamping die must be considered. At present, European and American customers generally require that the springback compensation should be handled well in the stamping die process design stage, and the springback should be within the product tolerance requirements.

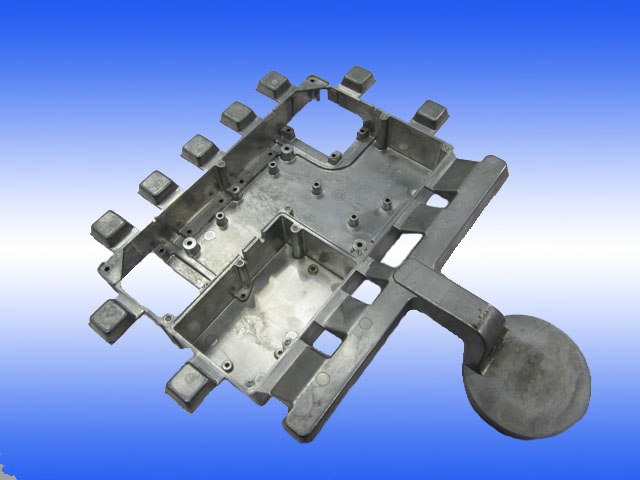

4. Blank holder force of automobile die blank holder

The forming process of blank holder force is an important technological measure. By continuously optimizing the blank holder force, the material flow direction can be adjusted and the stress distribution inside the material can be improved. The increase of blank holder force can make the part drawing more fully, especially the position of side wall and R angle. If the part is fully formed, the internal and external stress difference will be reduced, so that the springback will be reduced.

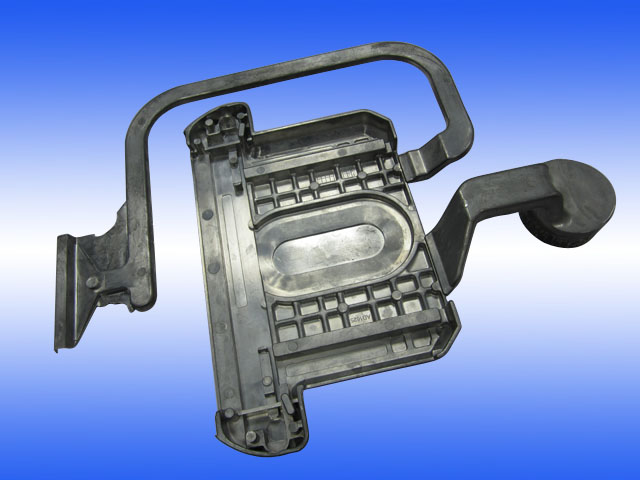

5. Automobile die drawbead

Drawbead is widely used in today's technology. Reasonable setting of drawbead position can effectively change the direction of material flow and effectively distribute the feeding resistance on the pressing surface, so as to improve the formability of materials. Setting Drawbead on the parts prone to springback will make the parts more fully formed, more uniform stress distribution, and thus reduce the springback.

Based on the above factors, in order to save the time of die adjustment and reduce the cost of subsequent die modification, it is generally necessary to use CAE simulation software for rebound analysis, rebound compensation and constant correction before determining the stamping process of automobile die. Commonly used software includes AutoForm, DYNAFORM and jstamp, etc.